Product Features

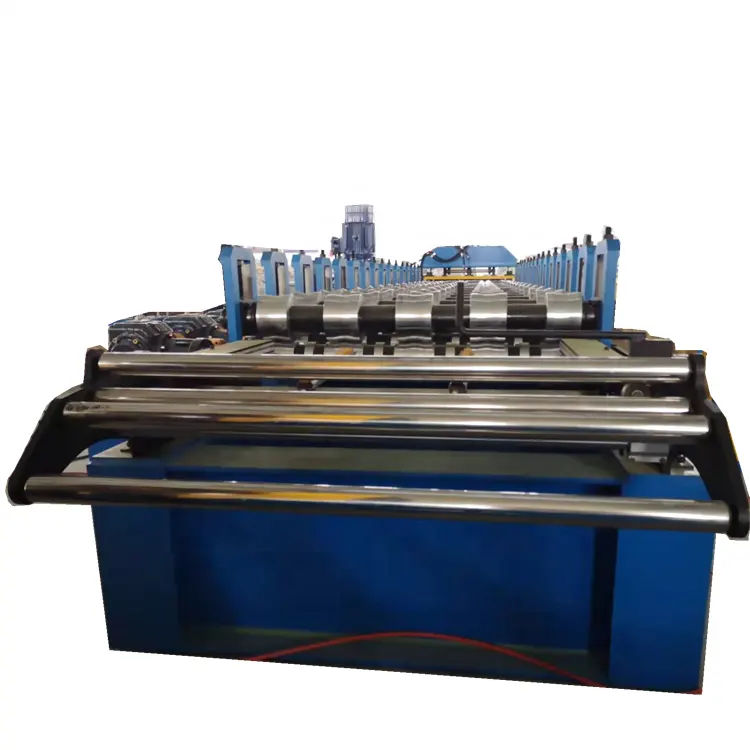

High Speed Trapezoidal Roof Tile Machine

This trapezoidal roof sheet forming machine can customize the tile length according to the requirements ,there is the construction of the computer controller to set up multiple sets of different data,easy operate.

The equipment automatically set in accordance with the computer data to produce different lengths of finished products.

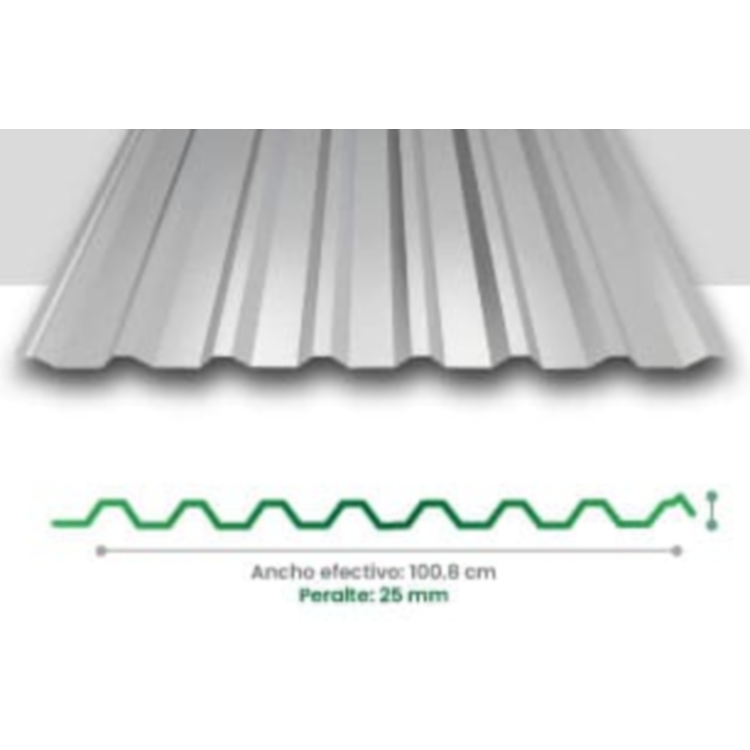

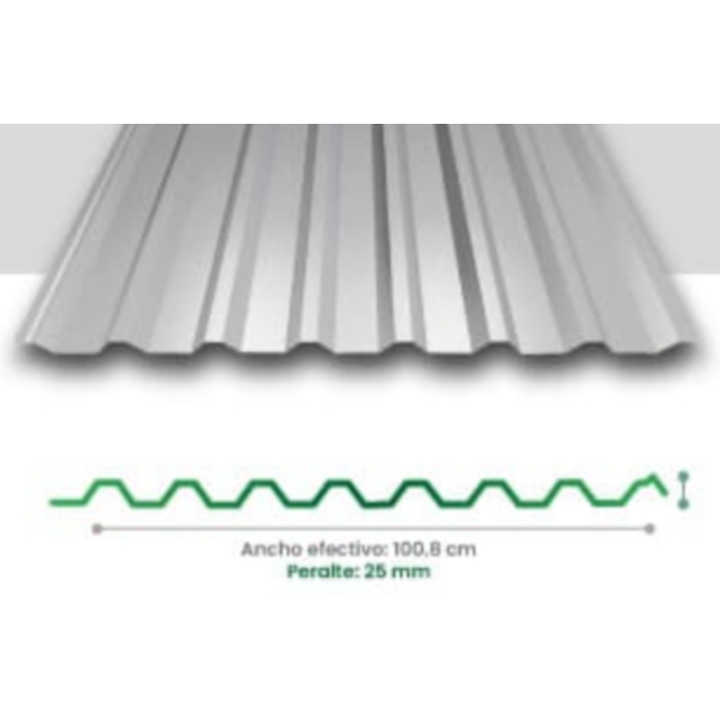

Profile drawing for reference:

Hydraulic decoiler

1. Has power, it can work automatically

2. Automatically adjust the decoiler to fit into the coil accorind to the coil diameter

3. With Pneumatic braking system

4. With press arm to keep coil from loosing in the operation of the high speed trapezoidal roof tile machine.

Entry Beach

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

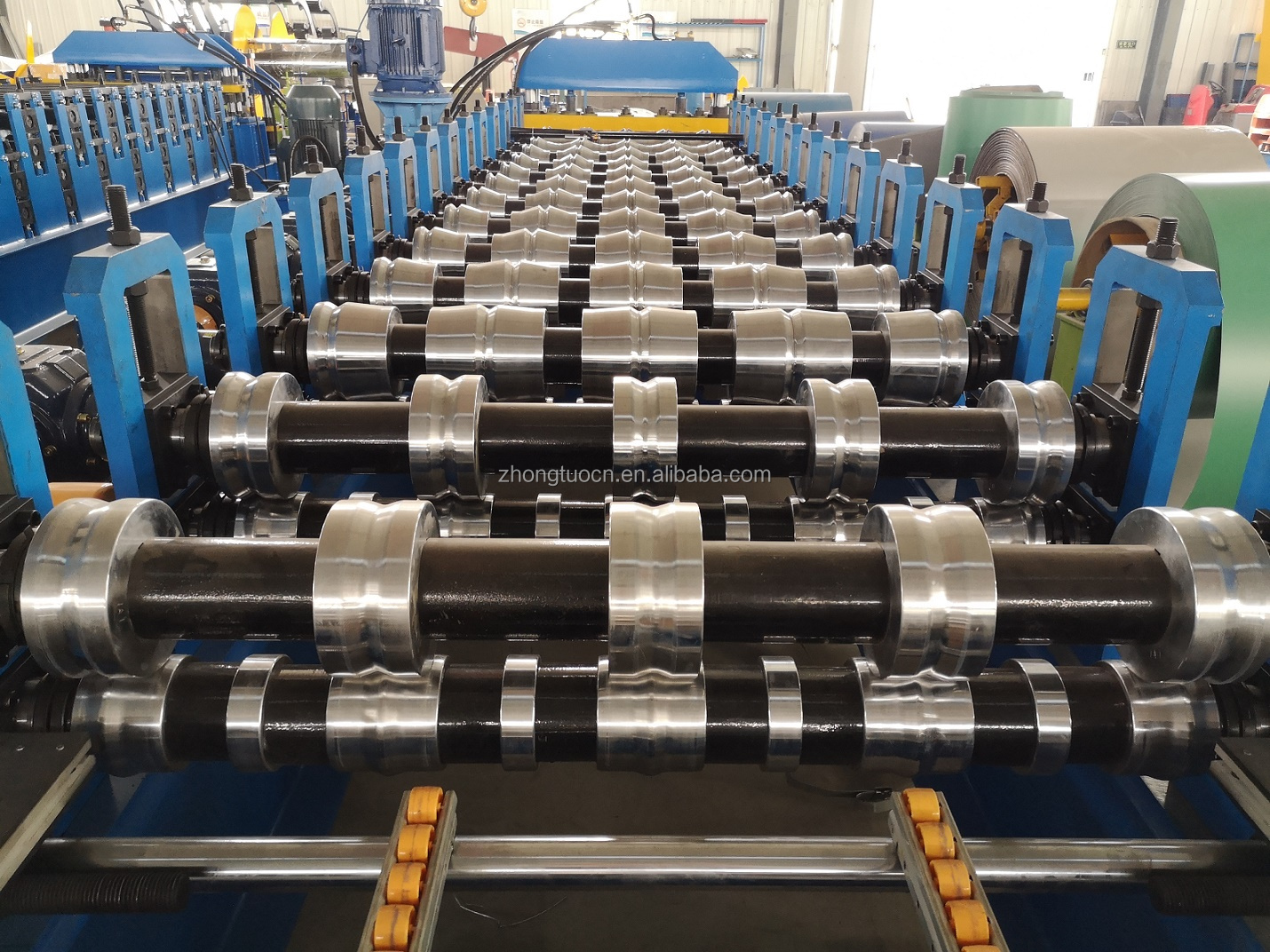

Roll forming device

1. Roller station: 26 rows(As your requirement)

2. Diameter of shaft: 80mm solid shaft

3. Material of rollers: 45# steel, hard chrome plated on the surface

4. Machine body frame: 400H steel

5. Drive chain: 1.2inch(As your requirement)

Hydraulic cutting device

We use pillars cutting system structure, it can make sure the cutting stable Hydraulic oil pump station will provide power to cutting system.

Hydraulic station

It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to

begin the cutting job.

PLC control System

The customer can set the desired product parameters, and the cutting system of the trapezoidal roofing sheet machine will produce the steel plate that meets your needs according to these parameters

1. PLC brand: Delta(Taiwan)

2. Frequency converter brand: Delta(Taiwan)

3. Encoder: Omron

4. Function: Automatic control the length,quantity and batch

Updated on January 23, 2024

PARAMETER

Formed Material:PPGI,GI,AI

Thickness:0.3-1.0mm

Width:1000mm/1250mm(customized)

Roller station:26 rows(As your requirement)

Diameter of shaft:80mm solid shaft

Material of rollers:45# steel, hard chrome plated on the surface

Machine body frame:350 H steel

Motor Power:5.5KW

Voltage:380V 50Hz 3Phase(As your requirement)

Control system:PLC

Forming Speed:15 - 20m/min

Cutting type:Hydraulic cutting

Hydraulic power:7.5kw

Cutting blade material:cr12mov material, no scratches, no deformation

Cutting tolerance:+/-1mm

VIDEO

PICTURE

FAQ

1. How to visit your company?

1.Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2.Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

2. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transporting.

3. What will you do if the machine is broken?

We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

4. Do you sell only standard machines?

No, most of our machines are customized according to customers specifications, also adopt top brand components.

5. Do you have after-sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across the world.

6. What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

7. How can we be assured that you will deliver us quality machine with spare parts ?

1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.8. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Geno Technology Development Hebei Co., Ltd

Mob.: 8613091162987

E-mail: web@geitgroup.com

WhatsApp: 8613091162987

Add.: N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Geno Technology Development Hebei Co., Ltd All Rights Reserved | Sitemap