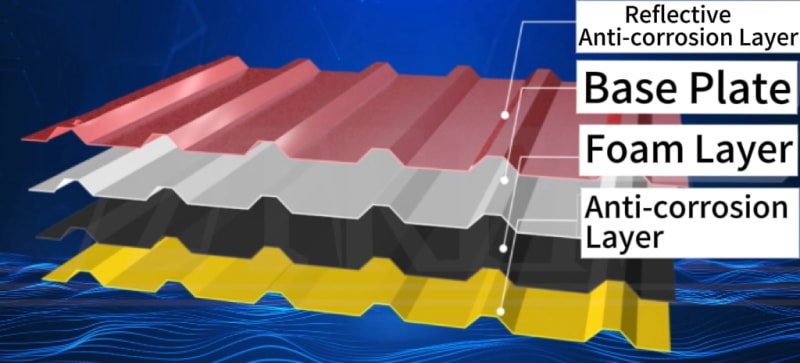

Top layer | Weather-resistant thermal insulation aluminum film |

Base layer | 0.5% magnesium aluminum zinc z50 |

Base layer | Rubber-plastic cotton + aluminum foil |

Advantages | Optimal thermal insulation and corrosion resistance |

Product Features

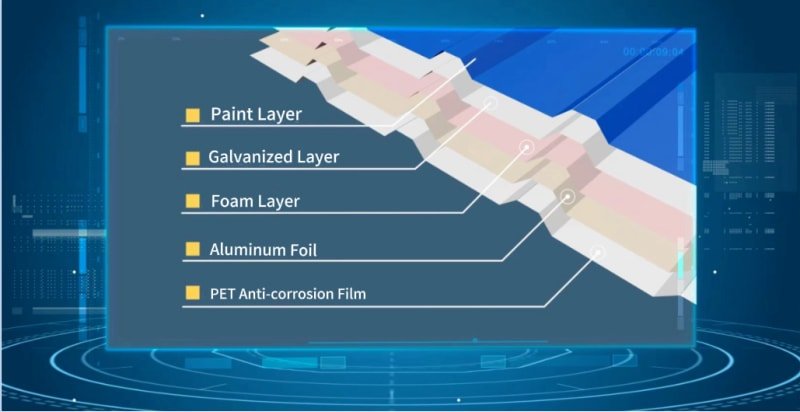

Anti-Corrosion Top Film (PEN)

Material | PEN (Polyester Film) |

Salt Spray Test | ≥12000 hours |

Accelerated Aging Test | ≥12000 hours |

Fire Rating | Class A1 (Test Report Available) |

Peel Strength | ≥5N/mm(23℃和-40℃) |

Solar Reflectance | ≥0.8 |

Thickness | 100 μm |

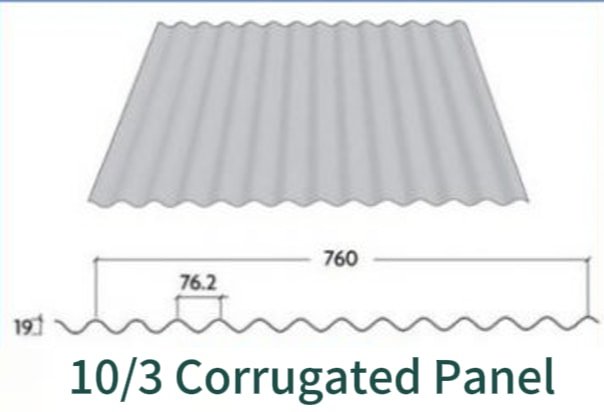

Standard | GB/T 12755《Corrugated steel sheets for construction》 |

Anti-Corrosion Bottom Film (PET)

Material | PET (Polyvinylidene Fluoride) |

Chemical Resistance Test | ≥120hours |

Neutral Salt Spray Test | ≥500hours |

Aging Test Standard | ASTM G154 or ISO 4892-3, ≥2000 hours, △E<5 |

Adhesion | ISO 2409 Cross-Cut, Grade 0 (No Peeling) |

Flexibility | T-Bend Test ASTM D4145, 1T/2T, No Cracks |

Processing Adaptability | No Cracks on Bending or Stamping |

Thickness | 75 μm |

PET coated color steel tile technical parameter table

Base material | Q235 carbon structural steel |

Standard | GB/T 25256-2010 or ASTM D882 |

Chemical Composition | Polyethylene Terephthalate (C₁₀H₈O₄)n |

Yield Strength | No distinct yield point (ultimate tensile stress used) |

Tensile Strength | ≥ 150 MPa |

Elongation After Fracture | ≥ 90% (According to ASTM D882) |

Top Sheet Thickness | 0.05 ~ 0.3 mm (Typical, Tolerance ±0.01 mm) |

Side Sheet Thickness | 0.05 ~ 0.3 mm (Customizable, Tolerance ±0.01 mm) |

Coating requirements

Coating type | hot-dip galvanized aluminum magnesium (ZM310) |

Coating Weight | Double side total ≥310 g/m² (single side ≥155 g/m²) |

Standard | GB/T 14978-2017 |

Adhesion / Corrosion Resistance | Meets the technical requirements of GB/T 14978-2017 |

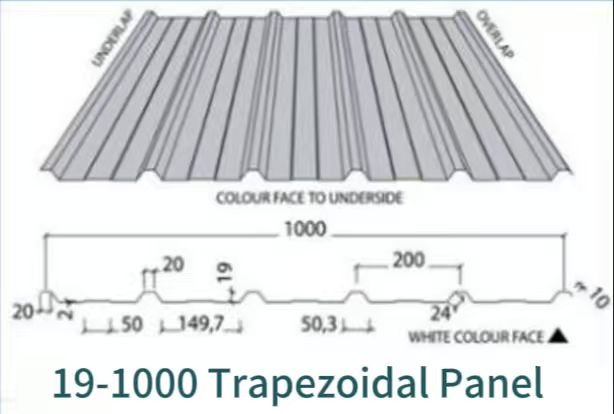

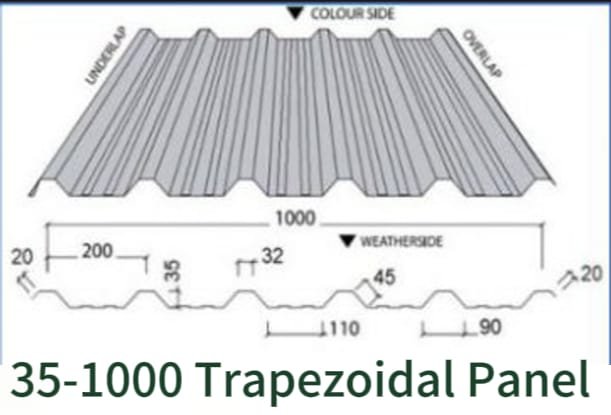

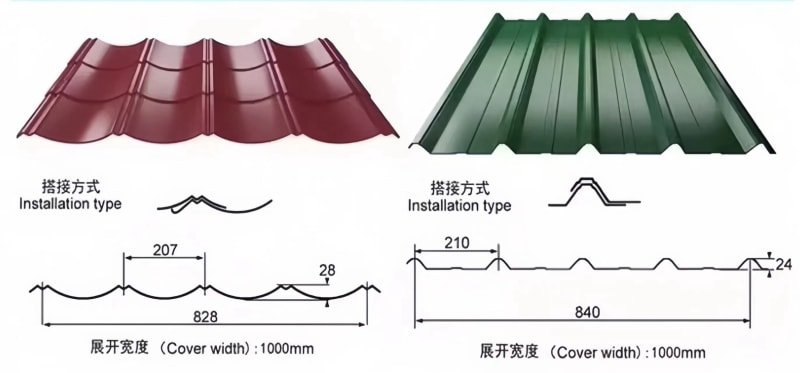

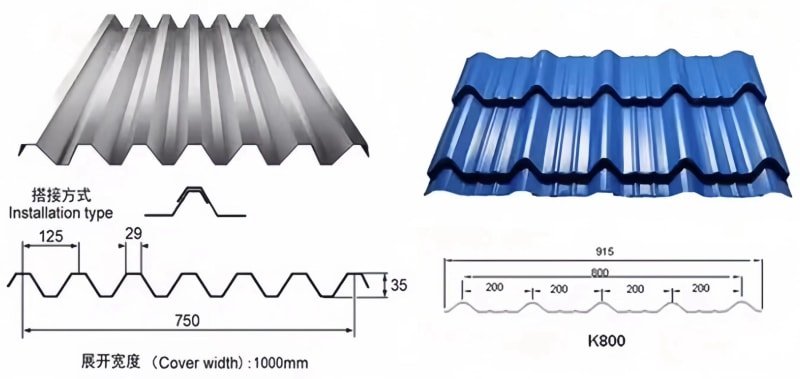

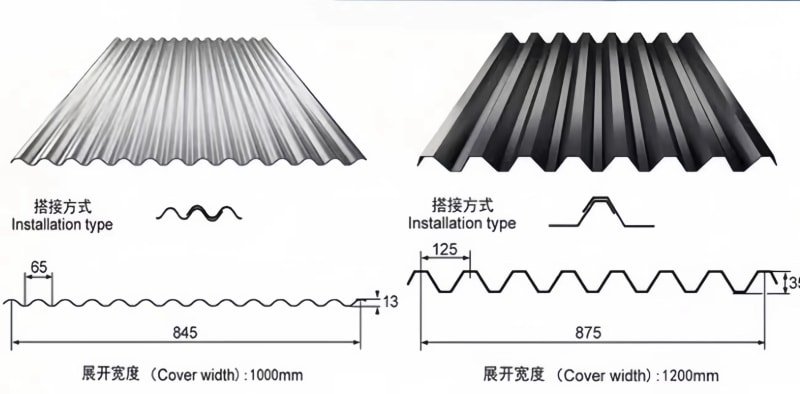

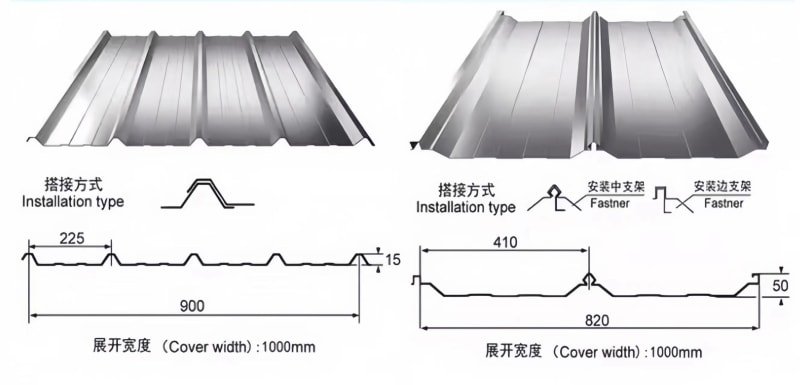

Profile and Dimensional Tolerance

Top Sheet Spec

| YX76-380-760, wave height 76 mm, effective width 760 mm, uncoiled width 1000 mm |

Side Sheet Spec | YX84-XXX-840, effective coverage width 840 mm |

Length Tolerance | ±5 mm (customizable by customer |

Other Technical Requirements

Surface Quality | No cracks or bubbles, uniform coating and film |

Marking (Top) | Q235/ZM310/1.0mm/760 Type |

Marking (Side) | Q235/ZM310/0.8mm/840 Type |

PARAMETER

VIDEO

PICTURE

FAQ

1. How to visit your company?

1.Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2.Fly to Tianjin airport, By high speed train From Tianjin to Cangzhou Xi (0.5 hour).

3.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

2. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transporting.

3. What will you do if the machine is broken?

We provide 1 year free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the roll forming machine.

4. Do you sell only standard machines?

No, most of our machines are customized according to customers specifications, also adopt top brand components.

5. Do you have after-sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across the world.

6. What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 45 workdays for delivery.

7. How can we be assured that you will deliver us quality machine with spare parts ?

1. Customers can come to our factory, or send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer's factory for the installation of the machine.8. Can you manufacture the roll forming machine according to my profile drawing or picture of finished product ?

Yes. Our rich experienced technical team can draft the accurate profile drawing, provide the most suitable technical solution for your required roll forming machine.

Geno Technology Development Hebei Co., Ltd

Mob.: 8613091162987

E-mail: web@geitgroup.com

WhatsApp: 8613091162987

Add.: N0.4 Road, Economic Develop Zone, Botou County, Cangzhou, Hebei, China

Geno Technology Development Hebei Co., Ltd All Rights Reserved | Sitemap